Experience and professionalism.

For over 45 years, Magneti Plastic has been synonymous with great professionalism and experience in the sector of the processing of compact rubbers, expanded filters in punched and sewn PPI and is a leader in the production and design of customized parts.

Modern structures and high-tech machinery,like the water-jet, they allow us to supply increasingly sophisticated products made according to the customer's needs. All the materials used in our processes comply with current regulations such as RoHs and Reach.

Experience, Quality, Care and History

Mr. Valter Giavazzi, thanks to the experience gained in the industrial sector for important leading companies in the household appliance, petrochemical and hydraulic sector, in 1973 founded Magneti Plastic.

In 1992, his daughter Raffaella began to support his father in the management of the company, expanding the production sectors over the years.

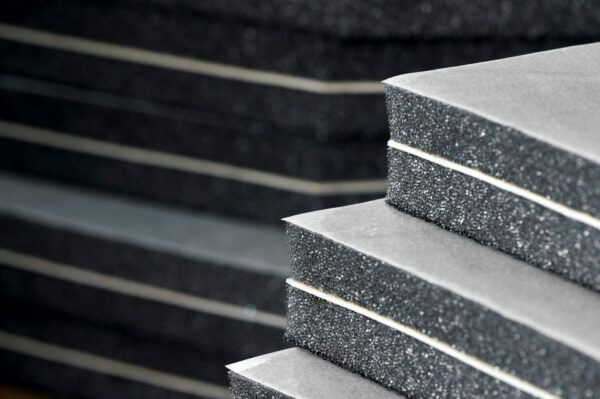

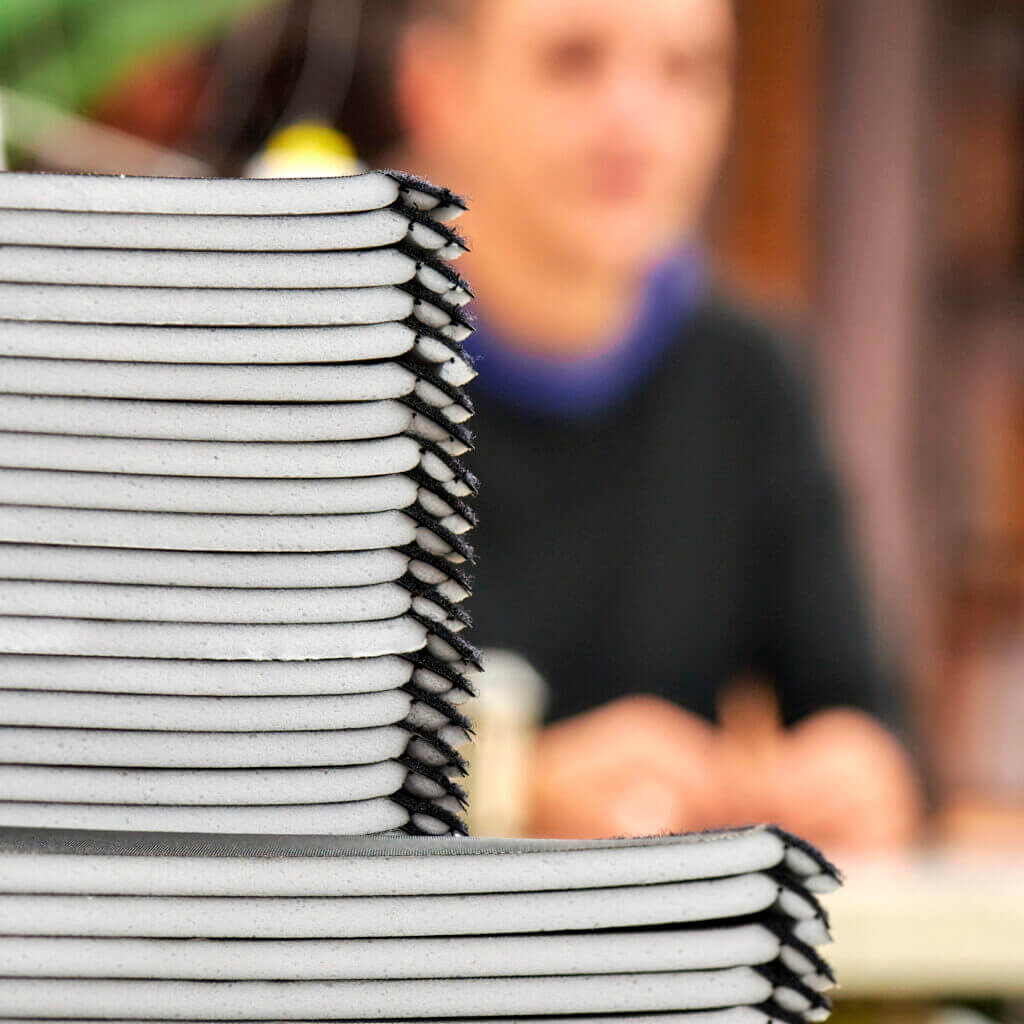

Currently the production ranges from soundproofing panels in polyurethane and Fonitek in sheet, to gaskets in natural and synthetic rubber, to foam filters sewn and shaped to design, to sleeves in polyester or nylon fabric, sewn directly on PVC rings.

In addition, the company manufactures heat shields sewn in expanded melamine for specific boilers for steam cleaning machines, stirrers and professional coffee machines.

All the materials used in the processing are fireproof, certified in class 1 and comply with current regulations such as RoHs and Reach.

The production of all items takes place internally in our blanking and sewing departments. The dedicated technical office, starting from the prototype provided by the customer, takes care of the soundproofing and / or insulation for the final sound level tests.

The company’s attention is also directed towards eco-sustainable solutions that protect the environment: in this regard it is worth remembering that our technical department uses and recommends the use of new rubber inserts capable of perfectly replacing lead, thus obviating the disposal problem.

Magneti Plastic has recently activated a nautical division in the province of Imperia for the production of sound-absorbing panels for engine rooms, made with top quality and innovative materials, both from the point of view of performance and from that of environmental sustainability.